In the landscape of natural colorants, blue has long been regarded as the “Final Frontier.” As global regulatory bodies further tighten restrictions on synthetic dyes, the Phycocyanin (Blue Spirulina Extract) supply chain has evolved from early “proof-of-concept” stages to a phase of mature industrial standardization. For industry veterans and stakeholders, the discourse in 2026 has shifted from simple availability to formulation stability and supply chain resilience.

I. Phycocyanin Supply Chain Resilience: From Biomass to Standardized Extraction

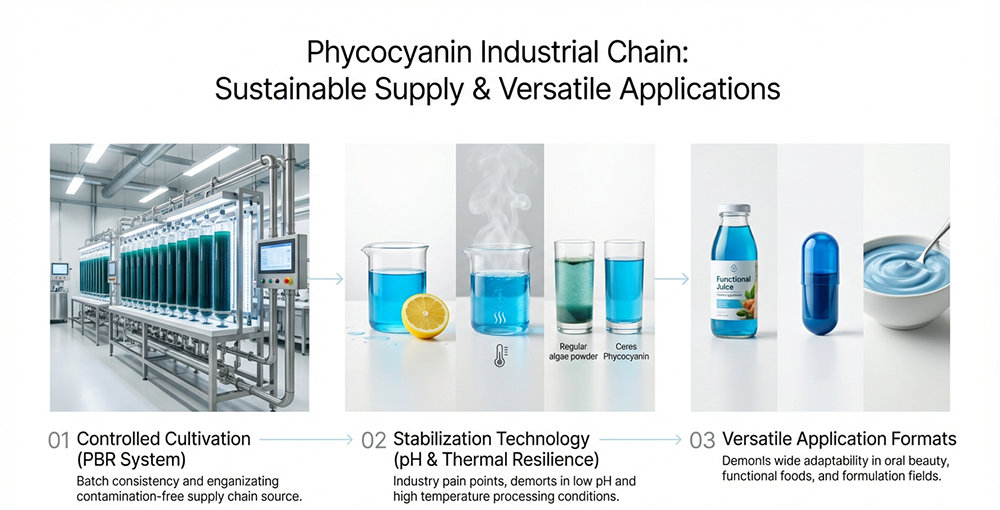

Historically, the Phycocyanin market was susceptible to the volatility of raw spirulina biomass. By 2026, leading suppliers like Ceres Biotech have successfully transitioned from traditional open-pond farming to controlled Photobioreactor (PBR) systems.

This industrial upgrade addresses the primary pain point in B2B procurement: batch-to-batch inconsistency in color value. Controlled environments effectively isolate the production from heavy metals and environmental pollutants, ensuring that the extracted Phycocyanin meets the most stringent Clean Label standards required for international trade.

II. Technical Breakthroughs: Enhancing Phycocyanin Stability in Low pH Environments

Traditionally, Phycocyanin faced significant challenges in acidic environments (pH < 4.5), where protein denaturation often led to color fading or precipitation.

In 2026, advanced stabilization techniques involving protein folding optimization and natural polysaccharide complexation have markedly improved the thermal and acid stability of the pigment. R&D teams can now confidently incorporate natural blue into low-pH Ready-to-Drink (RTD) teas and sports electrolyte beverages without risking sensory degradation during the product’s shelf life.

III. 2026 Technical Specifications: Precision Phycocyanin Selection by Dosage Form

For professional procurement managers, selecting the correct Phycocyanin specification based on the final delivery system is essential for cost optimization:

| Application Field | Recommended Phycocyanin Grade | Technical Priority | Supply Chain Value |

| Premium Nutraceuticals | High-Concentration E40 Powder | Minimizing tablet/capsule volume | Reduces logistics and packaging costs per dose. |

| Functional Foods | Standardized E25 Water Soluble | Instant dispersion & transparency | Ensures seamless integration into automated lines. |

| Cosmetics & Personal Care | Preservative-Stable Liquid | Microbial control & synergy | Simplifies blending in liquid-phase formulations. |

IV. Sustainability: The Carbon-Neutral Value of Natural Phycocyanin

Among the audience of an established industry platform, ESG metrics have moved from “nice-to-have” to a baseline requirement. The production of Phycocyanin is inherently a carbon-sequestration process. Compared to petroleum-derived synthetic blues, high-purity Phycocyanin can reduce the carbon footprint of a formulation by over 60%.

In 2026, through full-link digital traceability, brands can now provide consumers with verified data on the lifecycle of their colorants—from algae strain cultivation to final extraction. This transparency is no longer just a compliance measure; it is a competitive moat.

V. Conclusion: Moving Toward Mature Phycocyanin Partnerships

The market for natural blue colorants has outgrown the era of “trial and error.” For companies with a long-term vision, the priority has shifted toward partners who possess both R&D depth and scalable infrastructure. Phycocyanin is more than just a replacement for synthetic dyes; it represents a strategic investment in functional aesthetics and the sustainable bio-economy.

- Alice Wang

- Whatsapp: +86 133 7928 9277

- Email: info@demeterherb.com

Post time: Jan-12-2026