I. Market Context: Evolution from Simple Addition to Sensory Optimization

As the oral beauty market matures, the integration of bioactive ingredients into diverse formats—such as functional snacks and beverages—has become standard practice. The focus of R&D has shifted from mere “ingredient inclusion” to solving the technical challenges of how these raw materials affect the final product’s sensory profile (flavor and texture), physical state, and shelf-life stability.

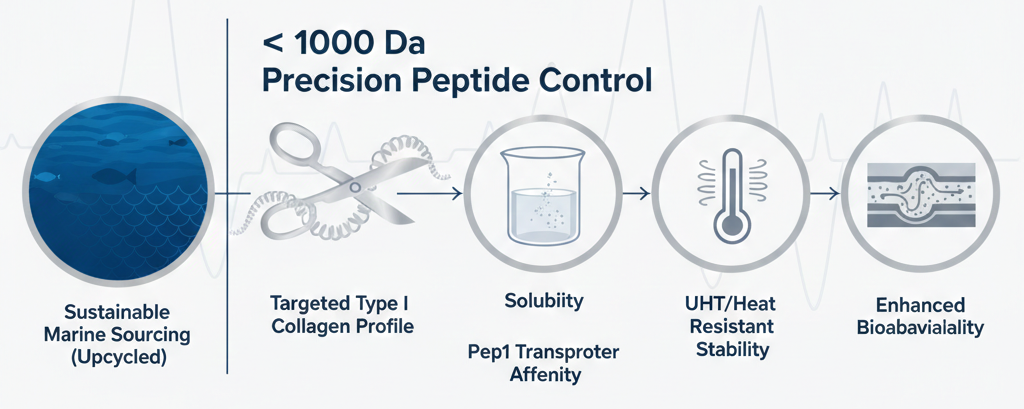

Hydrolyzed Fish Collagen Peptides have emerged as a preferred technical solution due to their specific molecular weight distribution and robust performance in complex food matrices.

II. Molecular Architecture and Bioavailability Kinetics

In the evaluation of collagen peptides, molecular weight distribution is the core metric determining both biological efficacy and processing performance.

-

Precision Enzymatic Hydrolysis: Modern processing allows for the precise reduction of fish collagen into peptides averaging below 1000 Da (Daltons). At this scale, the oligopeptides demonstrate high thermal and acid stability, maintaining their structural integrity even after undergoing Pasteurization or Ultra-High Temperature (UHT) sterilization.

-

Absorption Pathways: Pharmacokinetic data suggest that small-molecule fish collagen peptides are efficiently absorbed through the intestinal mucosa via passive diffusion or specific peptide transporters (such as PEPT1). This clarity in absorption mechanism provides a solid foundation for evidence-based product claims.

III. Formulation Performance: Stability in Diverse Food Matrices

The performance of fish collagen peptides varies across product formats, primarily dictated by their solubility kinetics and interaction with other ingredients.

-

High-Clarity Beverages: In transparent “beauty shots” or functional waters, fish collagen peptides exhibit exceptional light transmittance. Due to the minimal presence of residual proteins, they are less prone to flocculation or color degradation over the product’s shelf life—a critical factor for products using transparent packaging.

-

Gels and Confectionery: In collagen gummies or jellies, low-molecular-weight peptides do not significantly interfere with the cross-linking structure of hydrocolloids (like pectin or gelatin). This allows formulators to achieve high bioactive loading without compromising the desired elastic modulus or “chew.”

-

Powder Dispersion Systems: Fish collagen peptides possess moderate hygroscopicity and excellent flowability. In dry-blend processes, they demonstrate superior dispersion, minimizing clumping during terminal reconstitution by the consumer.

IV. Supply Chain Attributes: Compliance and Sustainability

In the framework of global supply chain management, raw material traceability and regulatory compliance are non-negotiable for brand security.

-

Clean Label Potential: Produced via natural enzymatic hydrolysis, the manufacturing process for fish collagen is transparent and avoids the use of harsh chemical solvents, aligning with the “Clean Label” movement.

-

Resource Efficiency: Derived primarily from upcycled marine by-products (skins and scales), fish collagen supports circular economy principles and offers a documented carbon footprint that is often lower than intensive terrestrial livestock farming.

-

Global Compliance: Marine-sourced materials are naturally free from risks associated with BSE (Bovine Spongiform Encephalopathy). Furthermore, fish collagen is widely recognized by global regulatory bodies and easily qualifies for Halal or Kosher certifications.

V. Technical Summary and R&D Recommendations

When selecting Fish Collagen Peptides as a core ingredient, formulation teams should prioritize the following technical parameters:

-

Uniformity of Peptide Distribution: Ensuring the majority of the molecular weight falls within the effective bioactive range.

-

Sensory Neutrality: Evaluating the baseline flavor profile in the absence of masking agents.

-

Synergistic Stability: Conducting stability testing in the presence of common co-ingredients such as Vitamin C, Hyaluronic Acid, or organic acids.

- Alice Wang

- Whatsapp: +86 133 7928 9277

- Email: info@demeterherb.com

Post time: Feb-13-2026